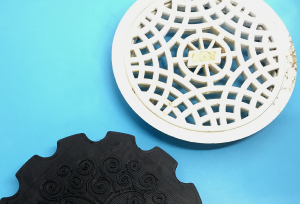

Customer case: Broken and less appealing floor drain covers in a Restaurant.

Often floor drains will dry out if water seldom is added and then an somewhat piquant odour might escape. Also the plastic floor drain covers are not very nice looking in a public space and they sometimes brake when stepped on.

My game changing solution?

A floor drain cover that:

-

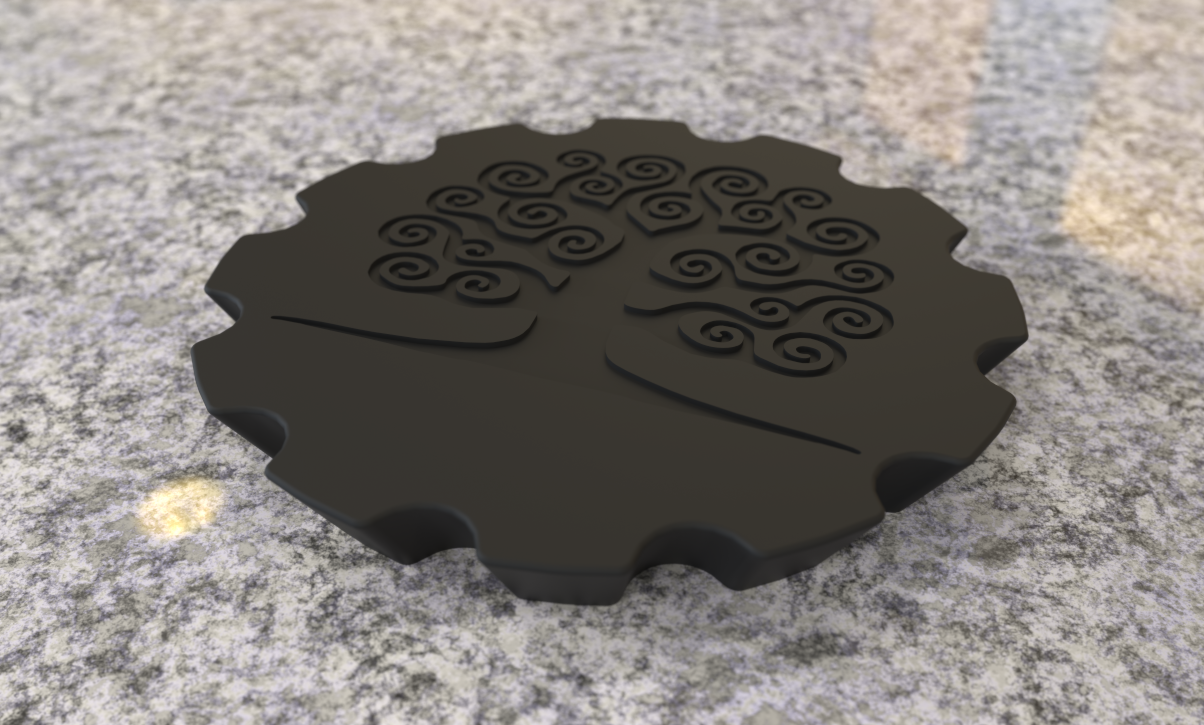

is 3D printed in TPU with the Restaurant logo featured on the top surface.

-

floats up when water enters the perimeter, if no water enters – it stops the water trap from drying out due to the insulation and sealing abilities.

-

will only flex when stepped on, will never brake (since its made of flexible TPU).

-

looks nice with its matte carbon black filled TPU material.

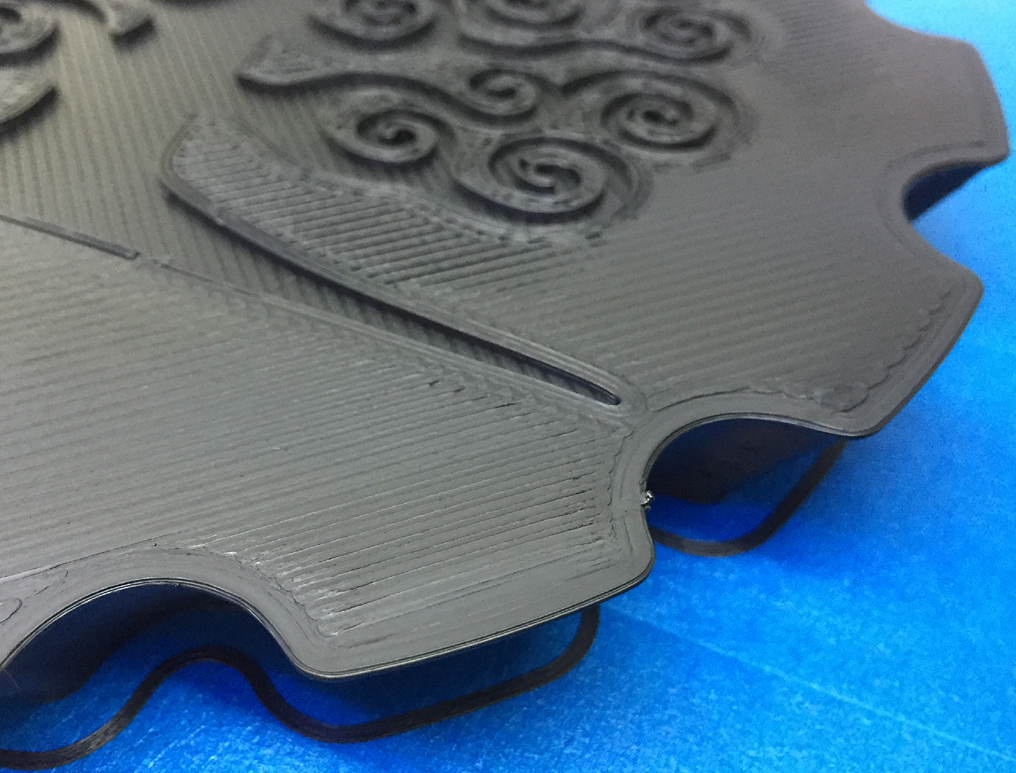

My ETPU 95-250 Carbon Black 3D printer filament material also gives a nice print with a minimum of stringy cobwebs (the TPU and carbon black mix makes for a favorable rheology and retraction settings can be optimized).

Less energy used when printing this ETPU since it does not need a heated bed (like ABS etc).

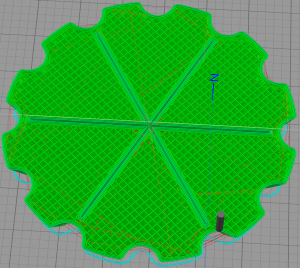

To prevent the cover from compressing too much under the foot I made some internal ribs, that way the infill (20%) can still be low and the final part will do a great job as a float.

It was printed with a 0.7mm nozzle at 230 deg C. To use a bigger nozzle than the commonly used 0.4mm gives the 3D print so many pros, for instance lower counter pressure in the melted material -> higher speed. The biggest advantage is the much stronger parts due to the better bonding between the layers (also makes it more likely to be water tight).

The conductivity is sometimes a main feature for using my ETPU material but in this case the surface finish and ease of 3D printing were the main drivers (the fact that conductivity is not a drawback in this case helped of course).

This drain cover was designed for this restaurant: http://orangeriet.vision/

My 3d print filament material (ETPU 95-250 Carbon Black) used for this part is for sale, more information is available here http://rubber3dprinting.com/