3DP “rubber” filament mod… or rubber-like fused filament fabrication (FFF)…

Hi and welcome, below you can see my work to modify the Makerbot Replicator (dual) so that it can print a rubberlike conductive and flexible TPU material. BTW my electrically conductive TPU used below can now be purchased here:

1.75mm / 2.85mm https://www.creativetools.se/palmiga

Also see the dedicated homepage:

So why did I want to print rubber? Well it´s sort of the missing link;) Now I can make: Dampers/Chock absorbers, Tires, Tank treads, Bellows, V-Belts, Timing/Synchronous Belts (or any other type to transfer power), Couplings, Grommets, Seals etc :-)

Step 1:

I have developed a suitable TPU filament, I named it PI-ETPU 95 Carbon Black, see some material data below:

| Diameter ø | 1,75 | mm | Aprox (always measure before use) |

| Density | 1,30 | g/cm³ | |

| Tensile Strength | 15 | MPa | ISO 527 |

| Yield Strength | 15 | MPa | ISO 527, 10x4mm part (not FDM) |

| Elongation at Break | 250 | % | 10x4mm part (not FDM) |

| Volume resistivity | <300 | Ωcm | PRE021, 10x4mm solid part |

| Surface resistance | <200.000 | Ωcm | IEC 61340-2-3, ANSI/ESD. STM 11.11, 400µm solid thick sheet |

| Hardness | 95 | Shore A | ISO 868 / D-2240 |

| Color | Carbon black | ||

| Recomended Temperature range | 190-230 | °C | Depending on 3D printer, nozzle and print speed |

| Self-ignition Temperature | >340 | °C | Aprox |

| Pre-drying | 90°C | for 1 hour | Only needed for optimal performance if the print surface starts to show small bubbles |

See some test prints further down on this page…

Step 2:

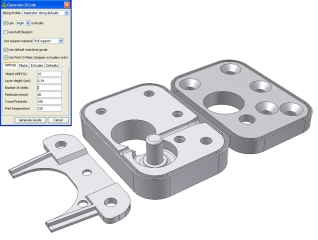

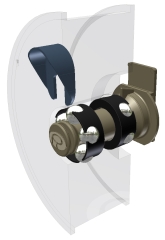

I designed a new “filament feeder assembly” for the Replicator, I call it PI Drive Block (original design can not handle soft high friction filament at higher speeds).

My first version of the PI Drive Block works really great for rubber, later I will upload the STL files to www.thingiverse.com but you can download it below now (It will not handle the standard plastic filament and it is designed for the Left extruder). The next generation will handle both rubber & plastic within the same footprint as the original but might be even more difficult to get accurate enough in the Makerbot (still work in progress).

If the demand is big enough I might even invest in tools to make real moulded parts to get the best performance/tolerances/reliability (yes I have the knowledge and connections needed).

DOWNLOAD THE PI Drive block

http://www.thingiverse.com/thing:458836

You could also try some other ball bearing versions like http://www.thingiverse.com/thing:33181 but the lack of guiding below the ball bearing is not good…

Step 3:

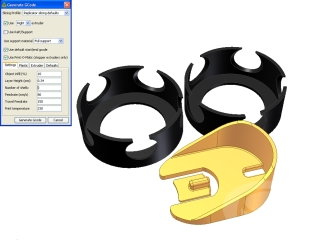

To get everything fully automated the 1/4″ feed-tube is replaced (going from the print head to the back) with a PTFE version tube. I also made an low friction spool holder suspension. Since the rubber is not as stiff as the plastic it can not turn the original spool holder without risking bad flow from the print head, with the original spool holder and feeder tube hand-turning is a must…

The new spool holder design works incredibly good, almost zero friction and also much faster/easier to unload/load a new spool :-) I designed it for glass marbles (aprox ø16mm) since most people have them easily available. Yes I will upload to www.thingiverse.com later… The parts need to be “glued” with acetone to get the best result.

Download the PI Spool Holder One-Piece

http://www.thingiverse.com/thing:458915

http://www.thingiverse.com/thing:458876

DOWNLOAD THE PI SPOOL HOLDER Screw Mount

http://www.thingiverse.com/thing:458902

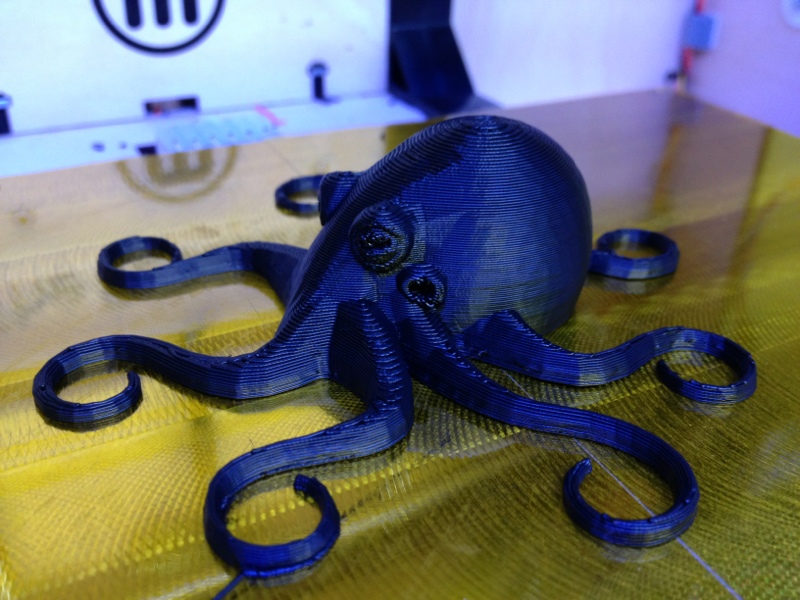

Test prints:

TEST 1. A test-print using PI-ETPU 95 Carbon Black, size 30x33x8mm, 4mm thick walls (layers=0.27mm, fill=100%, temp=220°C, feed=30mm/s, cold table):

See movie below: To avoid warpage I use the trick to add PVA-glue (in Swedish: Trälim ;o) to the surface to get a good “stickiness” http://sv.wikipedia.org/wiki/Polyvinylacetat. http://en.wikipedia.org/wiki/PVA_glue

See more tips on avoiding warpage here https://palmiga.com/design-2/design/warpage-curl-free-3d-printing/

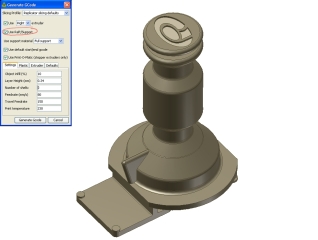

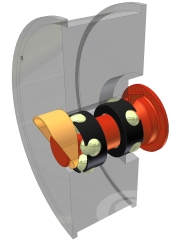

TEST 2. Another test-print using PI-ETPU 95 Carbon Black, this time the center piece of this 3D printed ø8 mm axle coupling (layers=0.34mm, fill=100%, temp=220°C, feed=35mm/s, cold table):

TEST 3. Size T5 synchronous/timing belt (and simple tank tread belt, later used in the quickly designed caricature WWI toy tank for my son: Renault FT-17) test-prints using PI-ETPU 95 Carbon Black, 1mm thick, 4mm wide, layers=0.34mm, fill=100%, temp=220°C, feed=35mm/s, cold table (Pulleys in ABS) As you can see the first print is a bit messy since the filament diameter settings was wrong. The 95 shore hardness secures a rather good traction power, it feels willing to transfer some power without stretching too much:

2013-10-01, PI-ETPU 95 Carbon Black successful extrusion

As you can see in the text below it has been problematic to find a skilled extruder company. I got tired of the mediocre tolerances they could deliver and said to myself – how hard can it be?

Ok so I purchased a small lab/hobby extruder, that one did not work either but I managed to design a new setup to get it right :-) and now I have several meters of filament within 0.05mm tolerance and a perfect smooth/glossy surface! I felt very satisfied when I finally hit the bed early this morning :-) Stay tuned…

2013-10-14, Perfect print result

Recently I have been making TPU “rubber” 1.75 filament myself since the different extruder companies I contacted could not reach the tolerances required. I have found a good technique and are now building a dedicated extruder that I can easily duplicate so that I can get a “extruder farm” up and running. All that takes time and for the fun of it I did a test print today, as you can see the result is amazingly good :)

See movies:https://palmiga.com/wp-content/uploads/2013/10/IMG_0364.mov https://palmiga.com/wp-content/uploads/2013/10/IMG_0359.mov

2014-03-10, Update

Sorry for the slow progress but now things are moving again. I´m running my 2:nd generation extruder and I made 2 rolls of filament this weekend. I measured the 2:nd roll´s filament diameter rather frequently (digital calliper) and the entire length was between 1.71 and 1.75 (+-0.02mm for approximately 0.9kg of TPU filament). Even if the calliper is not the most accurate method I´m still satisfied with that :-)

I have started 4 market trials to get some end user feedback on the material, 1 trial in Germany and 3 trials in Sweden. They are experienced and well known actors in the 3D-printing world. the feedback so far is great :-)

Now I´m designing the 3:d generation extruder and that version will be made in bigger volumes to really test the design.

Kind Regards /Thomas

2015-01-07, Update

Now things are moving again. I´ve run 5kg of 2.85mm filament this weekend with great tolerances :-) anyone that would like to buy samples can contact me here (also for 1.75mm) https://palmiga.com/contact/

Kind Regards /Thomas

The conductive TPU filament is for sale. Go here to find out more: http://rubber3dprinting.com/buy-material/